The fashion industry has long been synonymous with meticulous craftsmanship, where hours of painstaking handiwork transform raw materials into wearable art. Yet behind the shimmering curtains of high-profile runway shows, a quiet revolution is unfolding. 3D-printed accessories are dismantling traditional production timelines, offering designers an unprecedented blend of speed, precision, and creative freedom. A recent backstage report from a Milan Fashion Week showcase revealed how one avant-garde label slashed 300 hours of manual labor by integrating additive manufacturing into their accessory line—without sacrificing the intricacy that defines haute couture.

The Time Drain of Traditional Techniques

Handcrafted embellishments have always been the Achilles’ heel of fashion’s breakneck calendar. Before 3D printing entered the atelier, artisans would spend weeks sculpting molds, welding metal filigree, or stitching microscopic beads onto fragile fabrics. The report highlights a single showstopper headpiece from the collection: a geometric crown inspired by fractal patterns that previously required 80 hours of manual wire-twisting and soldering. Its 3D-printed counterpart emerged from the printer in 14 hours—fully assembled, with interlocking components that moved like kinetic sculpture. This wasn’t just efficiency; it redefined what was physically possible to create within a season’s constraints.

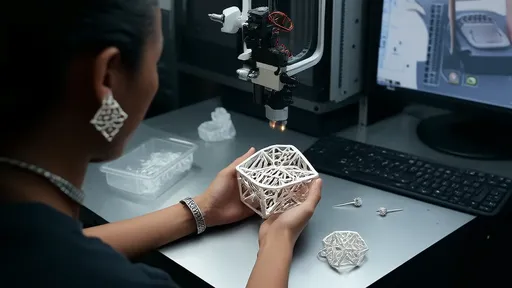

Material Alchemy: Beyond Plastic Stereotypes

Critics often reduce 3D printing to rigid plastics unfit for luxury finishes. But backstage, technicians demonstrated how sintering printers fused powdered titanium into featherlight lattice structures, while biodegradable algae-based filaments mimicked the drape of hand-tooled leather. One clutch bag’s "forged metal" appearance—originally achieved through lost-wax casting—was replicated using direct metal laser sintering (DMLS), cutting production time from three weeks to 56 hours. The secret lay in post-processing: a combination of electrolytic polishing and manual patina application preserved the artisanal aura while leveraging digital precision.

Democratizing the Unattainable

Perhaps the most disruptive revelation was how 3D printing reconciled exclusivity with accessibility. For a finale piece involving 200 unique feather-like components, designers uploaded parametric designs to networked printers across Europe. Local artisans then hand-finished each piece with custom dyes, enabling decentralized production that eliminated shipping delays. What once demanded a small army of specialists became a synchronized digital-physical workflow. The report notes this approach allowed last-minute design tweaks during fittings—a logistical impossibility with traditional methods.

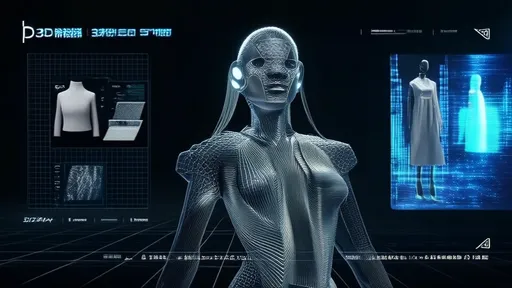

The Human-Machine Symbiosis

Far from replacing craftsmanship, the technology has spawned hybrid roles. "We now employ ‘digital blacksmiths’—artisans trained in CAD modeling who understand how to design for both printer capabilities and human touch," explained the collection’s creative director. This duality was evident in a corset belt featuring 3D-printed flexible hinges paired with hand-embroidered silk panels. The report emphasizes that the 300-hour savings didn’t eliminate human labor; rather, it redistributed time from repetitive tasks to conceptual innovation, with patternmakers now collaborating with programmers in real-time design iterations.

As dawn broke after the show’s triumphant debut, the implications extended beyond a single collection. The backstage data paints a future where 3D printing doesn’t just save time—it reimagines the entire ecology of fashion production, from atelier workflows to sustainable material loops. For an industry perpetually racing against the clock, these saved hours might just be the most valuable accessory of all.

By /Jun 25, 2025

By /Jun 25, 2025

By /Jun 25, 2025

By /Jun 25, 2025

By /Jun 25, 2025

By /Jun 25, 2025

By /Jun 25, 2025

By /Jun 25, 2025

By /Jun 25, 2025

By /Jun 25, 2025

By /Jun 25, 2025

By /Jun 25, 2025

By /Jun 25, 2025

By /Jun 25, 2025

By /Jun 25, 2025

By /Jun 25, 2025

By /Jun 25, 2025